Main services:

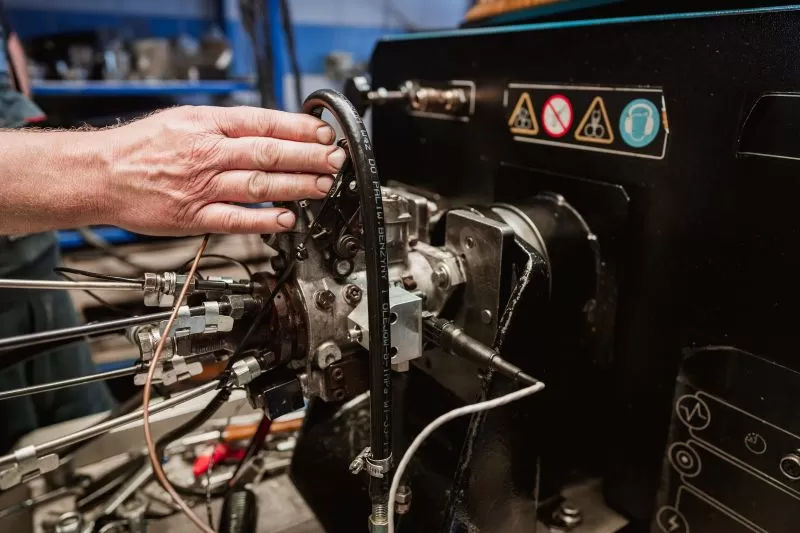

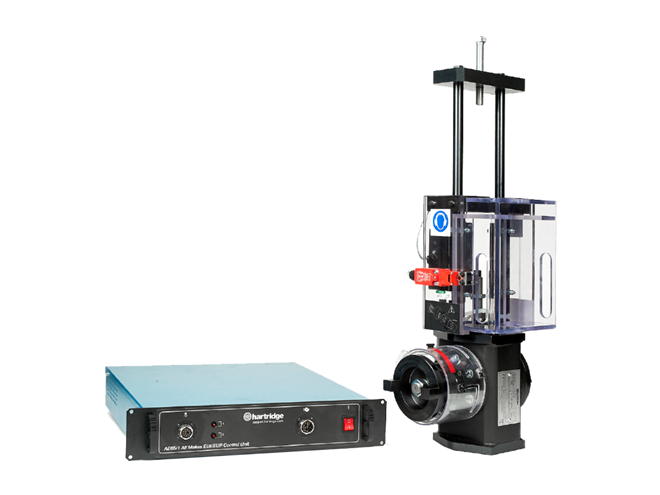

Thanks to our modern test benches, we are able to test:

CRp/GDp Pumps (all types and brands)

All EU6 Technologies (Denso HP5 and similar)

BOSCH CP4-EU6, VDO EU6 Technology

CRiN Injectors for Large Diesel Engines

Testing and Coding of HEUi / EUi / EUp